Click to play Movie

* SR-11000 is flagship of SEKONIC OMR scanner, and it could feed around 183 forms /min (A4, Letter, Legal applicable).

* It equipped Select stacker and Inline Printer normally.

* Select stacker has function to do reverse discharge. Sheets in Output Tray are stuck the same orders as were loaded onto the Input Tray.

* High capacity Input ADF Tray (Max: 500sheets) provides easy operation on high volume OMR mark forms.

* It equipped Select stacker and Inline Printer normally.

* Select stacker has function to do reverse discharge. Sheets in Output Tray are stuck the same orders as were loaded onto the Input Tray.

* High capacity Input ADF Tray (Max: 500sheets) provides easy operation on high volume OMR mark forms.

![]()

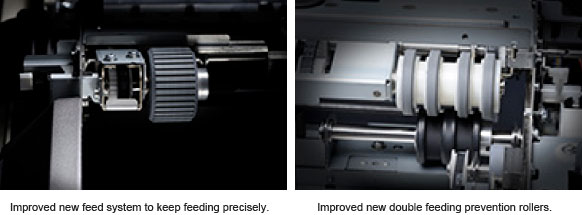

- Advanced paper handling technology

that ensures stable sheet feeding and handling

- New Prism Position Sensor that constantly monitor high speed feeding

The SR-11000 has 11 position sensors, including the new Prism Position Sensors, which precisely monitor the paper handling.

The sensors constantly monitor the sheets as they are being fed at high speed to ensure precise feeding. If a feed error is detected during operation, sheet feeding is immediately stopped to avoid or reduce damage to the following OMR sheets.

The sensors constantly monitor the sheets as they are being fed at high speed to ensure precise feeding. If a feed error is detected during operation, sheet feeding is immediately stopped to avoid or reduce damage to the following OMR sheets.

- Unique suction system that eliminates the causes of read errors

Our precisely designed misread prevention system is incorporated into the SR-11000. The new system can suction up materials, such as eraser shavings, sheet dust, and dirt, which can cause read errors, before the sheets reach the mark reading sensor. This new mechanism greatly reduces the number of cleaning cycles needed for the reading sensors, thus minimizing maintenance effort and cost.

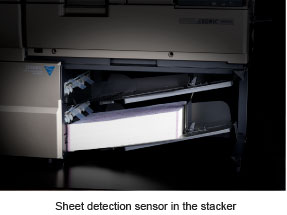

- Sheet detection sensor in the stacker that prevents users from forgetting to remove important OMR sheets

The SR-11000 has individual sensors installed in the main and selection trays to eliminate the danger of users forgetting to remove OMR sheets. Leaving OMR sheets in the tray during busy periods can result in much time being wasted sorting processed sheets.

The SR-11000 is designed to prevent human errors caused by the likes of forgetting to remove sheets.

The SR-11000 is designed to prevent human errors caused by the likes of forgetting to remove sheets.

- One-size-fits-all stopper with improved sheet alignment for better work

efficiency Adjustable sheet stopper

The stopper accurately collects the OMR sheets as they are being discharged at high speed. With a guide scale for nine standard sheet sizes, it can be adjusted for any sheet size with no steps.

Large numbers of discharged sheets can be stacked, leading to a major improvement in work efficiency for removed sheets.

Large numbers of discharged sheets can be stacked, leading to a major improvement in work efficiency for removed sheets.

- Reverse discharged function that discharges sheets in their original order

A reverse discharge function discharges the OMR sheets in their original order. Simply turning the discharged stack upside-down restores the order in which the sheets were loaded into the machine.

In addition, the tray design lets you easily remove the sheets from the front of the machine. In ways like this, we are constantly focusing on improving user-friendliness.

In addition, the tray design lets you easily remove the sheets from the front of the machine. In ways like this, we are constantly focusing on improving user-friendliness.

- Multi Layout for mixed types of OMR sheets

※Sheets must be of the same size and use the same mark pitch.

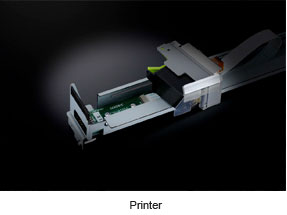

- Built-in ink-jet printer that reduces the work

to be performed after sheet processing

- Valuable option *Barcode

- MarkView software for SR-11000

MarkView can save Text or CSV file for easy to analyze by next application software.

- Approved and Compliant with worldwide environmental regulations.

BIS, BSMI, FCC, KCC, UL Approved. CE, RoHs Compliant