![]()

- ●

- FDM50A-ST is a torsional vibration type density meter for inline process applications. It can measure density and temperature in real time and continuously attached tank, and the pipe with the flange.

- ●

- It is a density meter of maintenance-free because it uses a piezoelectric ceramic as the driving unit.

- ●

- Density sensor portion (probe) is a complete sealed structure.

- ●

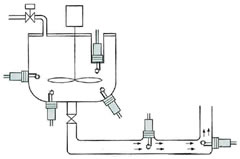

- It is possible to measure density in a state of the flow of liquid with attaching to the pipe and the agitating tank.

![]()

Also, in the case of a liquid containing the particles in intense sedimentation property, if a sufficient stirring, it can measure the density of the dispersed state. Cleaning is easy because it does not it use the bypass pipe, and incorporate the liquid inside equipment.

Since attachment portion of the equipment is adopted the flange, it can be installed anywhere in the tank and pipe.

The controller, displays temperature and density of the liquid in real time.

These data can be used as analog, and digital data.

![]()

- ●

- Density management of slurry

- ●

- The in-line measurement while ammonia water is reacting

- ●

- Alcohol concentration management in the brewing process

![]()

- ●

- FDM vibration type density meter is made up of the probe portion (detector), and the controller unit.

- ●

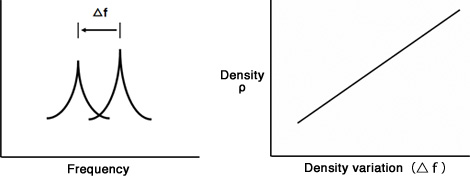

- Resonator having a resonance frequency of about 1kHz is in the probe and the tip is a density detector.

- ●

- Controller with the PLL circuit inside, controls to vibrate the prove at its resonant frequency.

- ●

- When the detector is immersed in the liquid, liquid enters the inside of the detection end. Inertia mass increases by the volume(density)of entered liquid the resonance frequency of the probe will become lower.

- ●

- Vibration density meter converts the value of the density from the change of the resonance frequency, Controller displays the density value.

- ●

- The controller , corrects by fluid viscosity and the temperature change and converts frequency density, it has been achieved (which may be affected by the viscoelasticity measurement accuracy) density measurement accuracy ± 0.001g / cm3.

![]()

*Left diagram example indicates a mounting and does not intend to reguire a plurality of probes.

![]()

| TYPE | FDM50A-ST | |

|---|---|---|

| Measuring Method | Vibration type (frequency displacement measurement) | |

| Density measurement range | Density | 0.500g / cm3 - 2.500g / cm3 (Range of viscosity measurements 1,000mPa・s following in FEM-1000V however) |

| Temperature | -10℃~70℃ | |

| Calibrating method | Compare density calibration with standard solution | |

| Display | Density | LED4 digit display (3 decimal places) |

| Temperature | LED4 digit display (1 decimal places) | |

| Analog output | Density | 4~20mA analog output(Output corresponding lower limit 0.000, the upper limit 2.500) |

| Temperature | 4~20mA analog output(Output corresponding lower limit -10.0, the upper limit 70.0) | |

| Digital output | RS-232C interface D-sub 9PIN output | |

| System requirements | Operating temperature and humidity | 5 ℃~50 ℃ / RH or less(Non-condensing) |

| Storage temperature | -20 ℃~70 ℃ / 80RH(Non-condensing) | |

| Power | AC90~240V 50 / 60Hz 25VA | |

| Weight and Dimensions | Probe | Mounting flange dimensions, of the non-wetted parts Φ70×H85[mm] Longest 54mm 2.2kg from the flange dimensions of wetted parts side |

| Controller | Mounting flange dimensions, of the non-wetted parts W200×D330×H168[mm] 4.7kg |

|

| Wetted Materials | Wetted parts SUS316L water pressure 0.98MPa | |

| Accessories |

Connecting cable (5m) 1 lines Power cable (2.5m) 1 lines 4~20mA cable (5m) 2 lines Instruction manual 1 expression |

|